Inspection

Rig ins GPS is providing the following kinds of inspection to Drilling / Work over Rigs and affiliates: Full package rig inspection (including CAT.4). To make full inspection to the rig parts / equipment’s according to:

- API 4FSpecification for Drilling and Well Servicing Structures.

- API 4GOperation, Inspection, Maintenance, and Repair of Drilling and Well Servicing Structures.

- API 5DSpecification for Drill Pipe

- API 7KDrilling and Well Servicing Equipment

- API 7LProcedures for Inspection, Maintenance, Repair, and Remanufacture of Drilling Equipment.

- API 8ASpecification for Drilling and Production Hoisting Equipment.

- API RP 8BRecommended Practice for Procedures for Inspections, Maintenance, Repair and Remanufacture of Hoisting Equipment.

- API 8CDrilling and Production Hoisting Equipment (PSL 1 and PSL 2)

- API 9ASpecification for Wire Rope

- API 16DSpecification for Control Systems for Drilling Well Control Equipment and Control Systems for Diverter Equipment.

- API RP 7G -2Recommended Practice for Inspection and Classification of Used Drill Stem Elements.

- API SPEC 6ASpecification for Wellhead and Christmas tree Equipment

- API SPEC 7Specification for Rotary Drill Stem Elements

- ASTM E 213Standard Practice for Ultrasonic Examination of Metal Pipe Tubing.

- ASTEM 317Standard Practice for Evaluating Performance Characteristics of Ultrasonic Pules- Echo Testing Systems Without the Use of Electronic Measurement Instruments.

- ASTM E 570Standard practice for Flux leakage examination of Ferro magnetic Steel Tubular

- ASTM E 709Standard Guide for Magnetic Particle Inspection.

- ASTM E 1316Standard Terminology for Non Destructive Examination.

- ASTM E 1324Standard Guide for Measuring Some Electronic Characteristics of Ultrasonic Examination Instruments.

- ASTM E 1359Standard Guide for Evaluating Capabilities of Non Destructive Testing Agencies.

- ASTM E 1065Standard Guide for Evaluating Characteristics of Ultrasonic Search Units.

- ASTM RP 8BHoisting Equipment.

- DS -1TMTH Hill Standard Drill Stem Design and Inspection.

- EMQSP 6.5Company SEA, MPI and Full Body Inspection System Prove-up.

- EMQSP 6.9Company Full-Length Pipe Body Inspection.

- ISO TS 29001Petroleum, Petrochemical and Natural Gas Industries-Sector Specific Quality Management Systems-Requirements for product and Service Supply Organizations.

- ISO 4309 & 4310Crane-Teat Code and Procedures crane-wire rope-Care and Maintenance.

- ISO 9927-1&3Crane-Inspection Part 1

- BSIBritish Standard Inspection.

- NS-2Drill String Inspection Standard, Fernley Proctor Group.

- IEC 60079-10-1 ED1.0 (2008-12)TC/SC 31J Explosive Atmospheres – Part 10-1: Explosive Gas Atmospheres.

- IEC 60079-10-2 ED2.0 (2015-01)TC/SC 31J Explosive atmospheres – Part 10-2: Explosive dust atmospheres.

- IEC 60079-14 ED5.0 (2013-11)TC/SC 31J Explosive atmospheres – Part 14: Electrical installations design, selection and erection.

- IEC 60079-17 ED5.0 (2013-11)TC/SC 31J Explosive atmospheres – Part 17: Electrical installations inspection and maintenance.

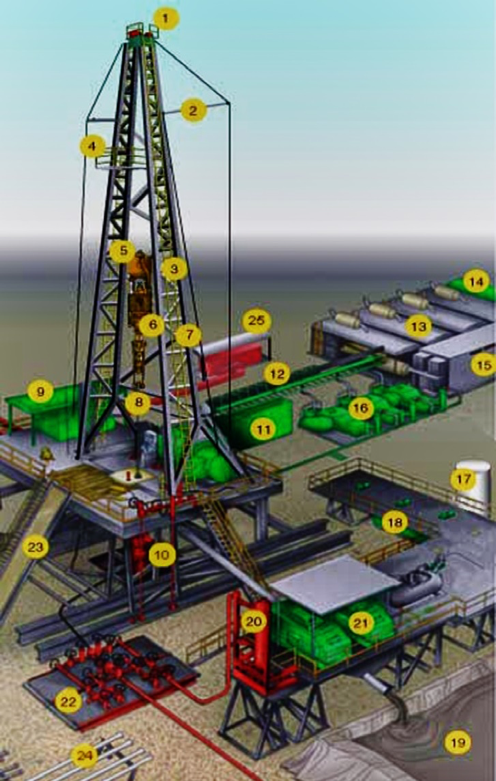

Rig Unit Inspection Parts

- 1-Crown Block and Water Table

- 2-Cat line Boom and Hoist Line

- 3-Drilling Line

- 4-Monkey board

- 5-Traveling Block

- 6-Top Drive

- 7-Mast

- 8-Drill Pipe

- 9-Doghouse

- 10-Blowout Preventer

- 11-Water Tank

- 12-Electric Cable Tray

- 13-Engine Generator Sets

- 14-Fuel Tanks

- 15-Electric Control House

- 16-Mud Pump

- 17-Bulk Mud Components Storage

- 18-Mud Pits

- 19-Reserve Pits

- 20-Mud Gas Separator

- 21-Shale Shaker

- 22-Choke Manifold

- 23Pipe Ramp

- 24-Pipe Racks

- 25-Accumulator

- 26-Annulus

- 27-Brake Bands

- 28-Casing Head

- 29-Cathead

- 30-Catwalk

- 31-Cellar

- 32-Conductor Pipe

Lifting Services

Lifting Appliances

- Portal cranes

- Overhead/gantry crane

- Self-loading arms/ HIAB

- Fixed lifting beams & Jacks

- Mobile Aerial Platforms

- Hoists

- Pad eyes (fixed structural)

- Forklifts

- Side booms

- Beam trolleys

- Sheave blocks

Lifting Accessories

- Chains and chain slings

- Shackles

- Beam- and Plate clamps

- Eye bolts & swivel rings

- Hoist rings

- Wedge sockets

- Safety harnesses

- Spreader beams

- Hooks

- Pad eyes and bolts

Lifting Equipment

- Containers

- Skips

- Drum racks

- Baskets

- Pipe racks

- Big bags

Lifting Operations Courses

- Rigging Loft Management Awareness.

- Lifting Equipment Inspection Training Course.

- Lifting Operation Supervisor Training Course.

- Management of Lifting Operations (Bs7121-Appointed Person).

- Forklift Operator Assessment Training Course.

- Fork Lift Truck – Refresher/Re-Certification Training Course.

- Mobile Crane Operator Assessment Training Course.

- Mobile Crane – Refresher/Re-Certification Training Course.

- Mobile Crane Supervisor Level Ii Training Course.

- Overhead Gantry Crane Assessment Training Course.

- Dropped Objects Awareness and Prevention Training Course.

Lifting Inspection

is an official British Standard institute Member which gives us the ability to ensure all work carried out by our engineers is in full compliance with all BSI standards. Having also the privilege for giving our clients an account under the umbrella of GAMMA to view all the latest standards It has been concluded that oil & gas company’s needs are nearly the same; however the degree of applying safety, following the standards and providing high quality is what determines which service company can satisfy those needs with the highest scale. We summarized the needs as the following:.

Lifting equipment supply:

It’s important to have the appropriate high quality material lifting equipment, with wide range of Supply products on hand when needed from some of the world’s leading manufacturers with Competitive prices.

Inspection services:

It’s necessary to inspect your lifting equipment frequently and give them their appropriate. Certification to ensure and maintain safe lifting operations. Lifting equipment require constant thorough examination every 6 & 12 months in accordance with Examination scheme.

Equipment hire:

Hiring lifting equipment is the solution for short-term period that could accomplish the demand of a Single item, Based on the client’s needs for cost control.

- Six Monthly LOLER SI 2307 Rig Survey.

- Drilling Handling Tools Inspection.

- NDT Inspection (MPI, PT, UT, RT, VT).

- Derrick Inspection.

- Crane Inspection.

- Dropped Object Survey.

- Lift Planning.

- Training Services.

- Engineering and Consultancy.

- Runway Beam Inspection.

- CCU Inspection DNV 2-7.1 BSEN 12079.

- Lifting Beam Inspection.

- Forklift Inspection.

- Over Head Travelling Crane Inspection.

- Winch Inspection.

- BOP Crane Inspection.

- Top Drive Inspection

2 – NSL (North Sea Lifting)

- LE1 LEI (Lifting Equipment Inspector) Module 1 General Lifting Equipment

- LE2 LEI (Lifting Equipment Inspector) Module 2 Winches & Powered Hoists

- LE3 LEI (Lifting Equipment Inspector) Module 3 Pedestal & Mobile Cranes

- LE4 LEI (Lifting Equipment Inspector) Module 4 Overhead Travelling Cranes, Runway Beams & Swing Jibs

- LE5 LEI (Lifting Equipment Inspector) Module 5

- LE6 LEI (Lifting Equipment Inspector) Module 6 Containers, Baskets & Other Cargo Carrying Units

Conventional NDT

- Visual Inspection& Remote visual inspection

- Radiography Testing (X –Ray & Gamma Ray) RT

- Ultrasonic Testing Shear wave (UT)

- Liquid Particle Testing (LPT)

- Magnetic Particle Inspection (MPI)

- Ultrasonic thickness measurement (UTT)

- Positive Material Identification (PMI)

- Infrared Thermography

- Ferrite Measurement

- Pressure testing (Hydrostatic & Pneumatic)

- Vacuum test

- Painting and coating inspection

- Ferrite Test (FT)